Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

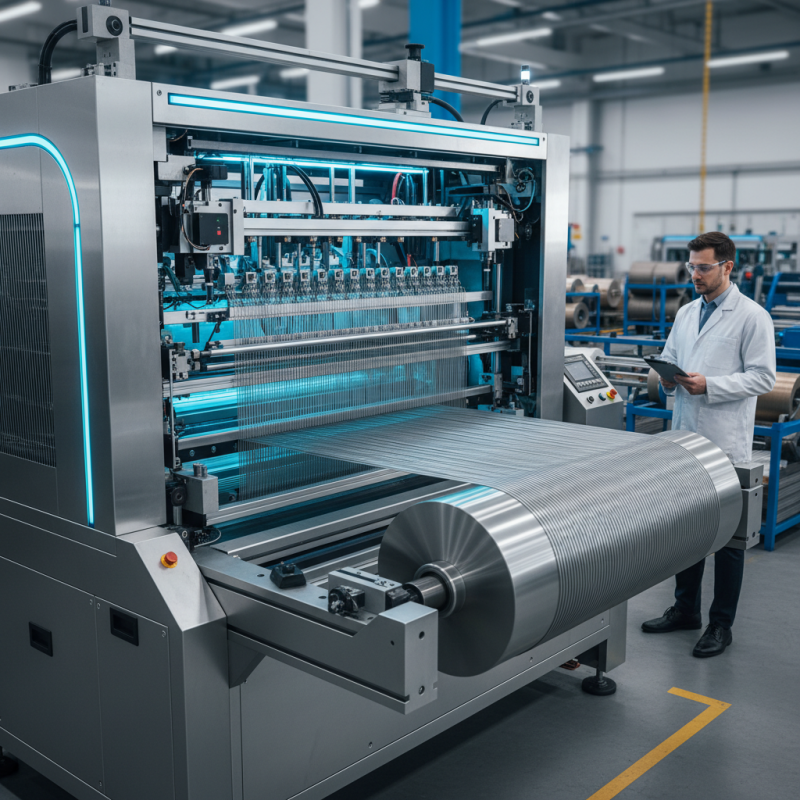

2026 Best Wire Mesh Weaving Machine for Your Industry Needs?

In the realm of industrial manufacturing, the wire mesh weaving machine stands as a pivotal tool for various applications. According to John Harmon, a leading expert in the wire mesh industry, “The right weaving machine can transform production efficiency.” His insights emphasize the importance of selecting the best equipment tailored to specific industry needs.

As industries evolve, so too do the technologies that support them. The 2026 wire mesh weaving machine innovations promise enhanced efficiency and precision. Manufacturers need to consider not only the cost but also the quality and adaptability of these machines. Many machines on the market may not truly meet operational demands, leading to wasted resources and time.

Therefore, a thoughtful selection process is essential. Identifying the right wire mesh weaving machine can significantly impact productivity and product quality. The goal should be to find a machine that not only fits current requirements but also anticipates future challenges.

Overview of Wire Mesh Weaving Machines and Their Applications

Wire mesh weaving machines are essential in numerous industries. They produce strong, flexible products. Applications include construction, agriculture, and filtration. The machines cater to diverse material requirements. Stainless steel, aluminum, or plastic mesh options exist. Each material serves specific needs.

Tips: Consider your project's demands. Identify the required mesh size. Smaller openings are best for filtration. Larger openings suit construction and reinforcement.

While choosing a machine, assess its speed and efficiency. Some machines require constant monitoring. Others may need adjustments for different materials. This can affect production time. A machine may excel in one area but falter in another. Finding the right balance is crucial.

Proper maintenance can prolong a machine's life. Regular cleaning and lubrication help maintain efficiency. Ignoring wear and tear can lead to costly repairs. Investing time in upkeep is wise.

Key Features to Consider When Choosing a Weaving Machine

When selecting a wire mesh weaving machine, key features significantly impact efficiency and output quality. Manufacturers often prioritize durability and speed, aligning with industry trends. Reports show that a durable machine can increase production rates by 20%. This is critical since many industries demand high-output solutions.

Machine efficiency hinges on technology. Cost-effective machines should utilize advanced CAD software for design purposes. Embracing automation is also crucial. Studies indicate that automated weaving processes improve precision, reducing human error. This shift is essential as industries increasingly favor high-quality standards.

Maintenance requirements are another vital consideration. Machines that offer easy maintenance can reduce downtime significantly. A recent survey revealed that over 30% of manufacturers face delays due to complex maintenance needs. Therefore, ensuring easy access to parts and maintenance schedules can enhance overall productivity. Evaluating these features carefully can tailor a weaving machine to fit specific industry requirements.

Comparison of Top 2026 Wire Mesh Weaving Machines

When selecting a wire mesh weaving machine for your industry needs, you face various options. Each machine has unique features and specifications. Some machines offer higher speeds, while others emphasize flexibility and ease of use. Understanding these differences is crucial for making the right choice.

For instance, a machine with advanced automation can significantly increase production rates. However, it may require a steep learning curve. Simpler models might be easier to use but could lack some efficiency. Consider your team’s skills and the machine’s operational complexity. Will your operators adapt quickly, or will training be necessary?

Moreover, assessing durability and maintenance needs cannot be overlooked. Some machines are robust but demanding in upkeep. Others are more forgiving but might not endure heavy use. Investing time in understanding these factors will lead to better long-term performance. Don't rush the decision; take your time to evaluate all aspects.

2026 Best Wire Mesh Weaving Machine Comparison

The following chart compares key specifications of top wire mesh weaving machines for 2026, evaluating factors such as production speed, machine weight, and energy consumption.

Industry-Specific Needs: Tailoring Machines for Different Sectors

When selecting wiring mesh weaving machines, industry-specific requirements must be considered. Each sector shows unique needs. For example, the automotive industry requires precision and durability. In contrast, agriculture might prioritize flexibility and ease of maintenance. According to recent market research, the demand for specialized weaving machines has grown by 15% annually.

Tips: Focus on the specific material types your industry uses. This can lead to better machine selection. Using the right machine improves productivity and reduces waste.

Another aspect to ponder is the machine’s adaptability. Can it handle various mesh sizes? This is essential for industries like construction, where specifications vary widely. A versatile machine can save costs over time. Reports suggest customized machines can extend operational lifespan by up to 30%.

Tips: Always compare the longevity and maintenance requirements of machines. Cheaper options may not always be the best choice. Consider the long-term investment value in your final decision.

Maintenance and Support for Wire Mesh Weaving Equipment

Maintenance of wire mesh weaving machines is vital for optimal performance. Regular inspections can catch issues early. Operators should routinely check for wear and tear. Lubrication is key to keep moving parts functioning smoothly. A well-lubricated machine runs quieter and lasts longer.

Support for these machines goes beyond maintenance. Training your staff is essential. They should understand how to operate the equipment safely. Misuse can lead to costly breakdowns and repairs. Spare parts should be readily available. A delay in sourcing parts can halt production. Having a local supplier can ease this burden.

Investing in maintenance and operator training can save money in the long run. Keep detailed records of maintenance performed. This will help identify recurring issues over time. Reflecting on past incidents can improve future practices and enhance overall efficiency. Addressing these areas ensures your machines stay reliable and efficient.