Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

Best EMI Filters for VFD Applications What You Need to Know

In today’s rapidly advancing industrial landscape, the role of EMI filters in Variable Frequency Drive (VFD) applications is crucial. As expert James Nguyen, a leading authority in electrical engineering, stated, "EMI filters for VFDs are essential for reducing noise and improving equipment longevity." This statement highlights the importance of a well-functioning EMI filter for VFD, which is often overlooked.

VFDs generate significant electromagnetic interference (EMI) due to their switching technology. An effective EMI filter mitigates these effects, ensuring smoother operation. Poorly managed EMI can lead to equipment failures and costly downtimes. The right EMI filter for VFD not only protects machinery but also enhances overall system performance.

Choosing the ideal EMI filter requires understanding specific needs. Not all filters suit every application. Some users may underestimate the complexity involved. It's not just about installation; it's about compatibility, performance, and long-term reliability. Regular assessments and adjustments are vital as technology evolves. This constant reevaluation ensures the best protection against EMI.

Understanding EMI Filters and Their Importance in VFD Applications

Electromagnetic Interference (EMI) filters are crucial in Variable Frequency Drive (VFD) applications. They help reduce noise and ensure stable operation. In a report by the International Electrotechnical Commission, up to 40% of electrical anomalies are linked to EMI issues. These filters create a barrier, preventing interference from affecting sensitive equipment.

Noise can disrupt communication between components. A clear signal is vital for optimal performance in industrial settings. According to research by the National Institute of Standards and Technology (NIST), poorly shielded systems can lead to efficiency losses of up to 30%. For companies reliant on VFDs, those losses can mean thousands in wasted energy and potential downtime.

Selecting the right EMI filter requires careful consideration. Factors such as frequency range and power rating are key. Yet, many firm choices are based on assumptions rather than well-defined data. Overcoming this challenge is necessary for better efficiency. Engineers must adopt a data-driven approach to filter selection, ensuring minimal interference and improved performance.

Types of EMI Filters Suitable for Variable Frequency Drives

In Variable Frequency Drive (VFD) applications, EMI filters are crucial for reducing electromagnetic interference. Different types are available, and each serves a unique purpose. Commonly used filters include capacitive, inductive, and common-mode designs.

Capacitive filters help block high-frequency noise, while inductive filters reduce low-frequency spikes. Common-mode filters focus on noise from multiple sources. Selecting the correct filter can be overwhelming. It's essential to assess your specific needs, power ratings, and operational environments, as not all filters suit every application.

Improper filter selection may lead to performance issues. Some users overlook the importance of installation; incorrect positioning can minimize the filter's effectiveness. Test results may vary if conditions change. Regularly reevaluate your setup to ensure optimal performance.

Key Specifications to Consider When Choosing EMI Filters

When selecting EMI filters for VFD applications, there are key specifications to consider. Filtering capability is essential. Look for filters that can effectively reduce common-mode and differential-mode noise. A good filter helps maintain performance and prevents interference.

Another important aspect is the voltage rating. Ensure that the filter can handle the maximum voltage of your VFD system. Underestimating this may lead to failures or reduced efficiency. Current rating also matters. The filter should support the operating current without overheating.

Additionally, consider the insertion loss. This indicates how well the filter performs at specific frequencies. Higher insertion loss means better protection from EMI. Look at the filter's size and mounting options, too. Some systems have space constraints. Finding the right fit can be tricky. Reflecting on these aspects can prevent costly mistakes and ensure optimal operation.

Installation Best Practices for EMI Filters in VFD Systems

When installing EMI filters in VFD systems,

attention to detail is key. Proper placement of filters affects performance. Filters should be

as close as possible to the VFD input. Avoid long leads, as these can introduce unwanted

noise. This setup minimizes electromagnetic interference and improves overall

efficiency.

Tip: Use short, twisted wires for

connections. This reduces inductance and radiated emissions. Ensure grounding practices

are followed. A solid ground connection is essential. It can make a significant difference

in filter effectiveness.

Consider the environment when installing filters. High temperatures or moisture can impact

performance. Evaluate the location and ensure proper ventilation. Look for signs of

wear and tear in your system. Regular checks can prevent costly failures. Adjustments may be

necessary to maintain optimal operation.

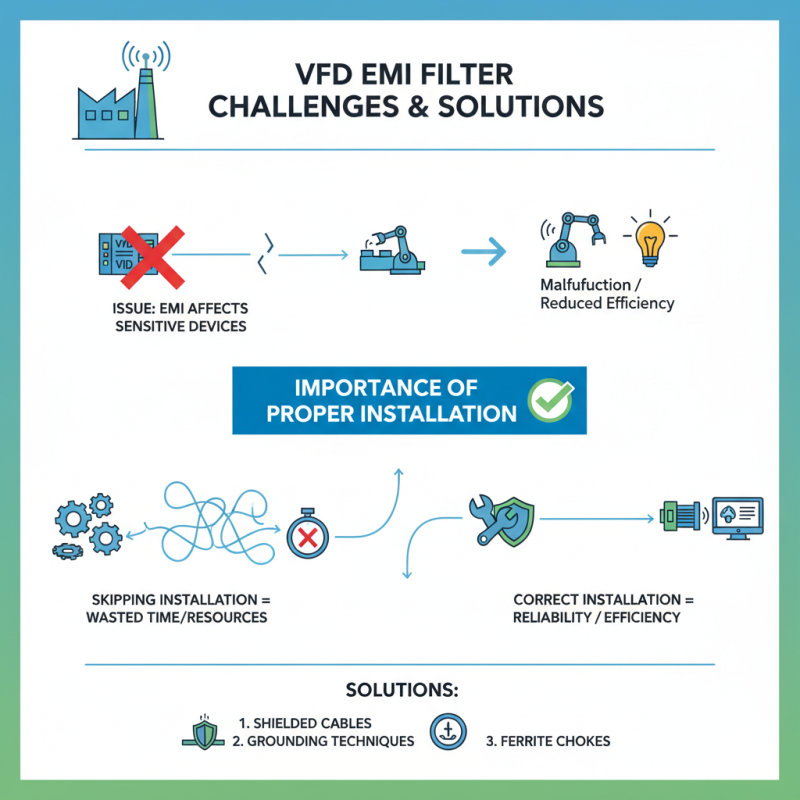

Common Challenges and Solutions When Using EMI Filters

When it comes to using EMI filters with Variable Frequency Drives (VFDs), several challenges often arise. One typical issue is electromagnetic interference affecting sensitive devices. This can lead to malfunctioning or reduced efficiency. It’s essential to recognize the importance of proper filter installation. Skipping this step may waste time and resources.

Tips: Always double-check your connections. Ensure that the filter is correctly aligned with the VFD. This simple step can prevent significant problems down the road.

Another common challenge is the selection of suitable filter types. With various options available, making the right choice can be confusing. Inappropriate filters can cause increased energy losses. These losses may result in overheating or inefficiency in system performance. It’s crucial to consider the specific environment and application requirements when selecting.

Tips: Consult with experts to determine the best EMI filter type. Their insights can guide you, ensuring better choices for your specific needs.

Lastly, maintenance can become an overlooked aspect of using EMI filters. Neglecting regular checks can lead to deterioration in performance. Accumulated dust or wear can significantly impact the filter’s effectiveness over time. Remember to schedule routine inspections to maintain optimal functionality.

Tips: Keep a maintenance log. Document performance issues and resolutions, helping you identify recurring problems and improve your setup effectively.

Related Posts

-

Top 5 EMI Filter Types to Enhance Your Electronics Performance

-

How to Select the Right Motor Inverter for Your Industrial Application

-

Understanding the Benefits of Variable Speed Drives in Modern Industry

-

Unlocking Efficiency in Industrial Applications How to Use the Best Single Phase to 3 Phase Converter VFD

-

Why Choose a Gear Reducer for Your Mechanical Needs?

-

Exploring the Impact of ATO Single Phase VFD on Energy Efficiency and Cost Savings in Modern Applications