Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

7 Best Ways to Enhance Efficiency with Single Phase AC Drive

In the rapidly evolving landscape of industrial automation, the demand for energy-efficient solutions has never been more critical. According to a report by the International Energy Agency (IEA), industrial sectors account for nearly 37% of global energy consumption, underscoring the importance of optimizing power usage. One effective way to achieve this is through the implementation of a single phase AC drive, which has shown to reduce energy costs by up to 30% in various applications. These drives not only enhance operational efficiency but also extend equipment lifespan and minimize maintenance costs. As industries increasingly turn towards sustainable practices, understanding the best methodologies to leverage single phase AC drives becomes essential for maximizing productivity while minimizing environmental impact. This guide outlines seven best practices to help businesses enhance their efficiency using single phase AC drives, paving the way for smarter and greener operations.

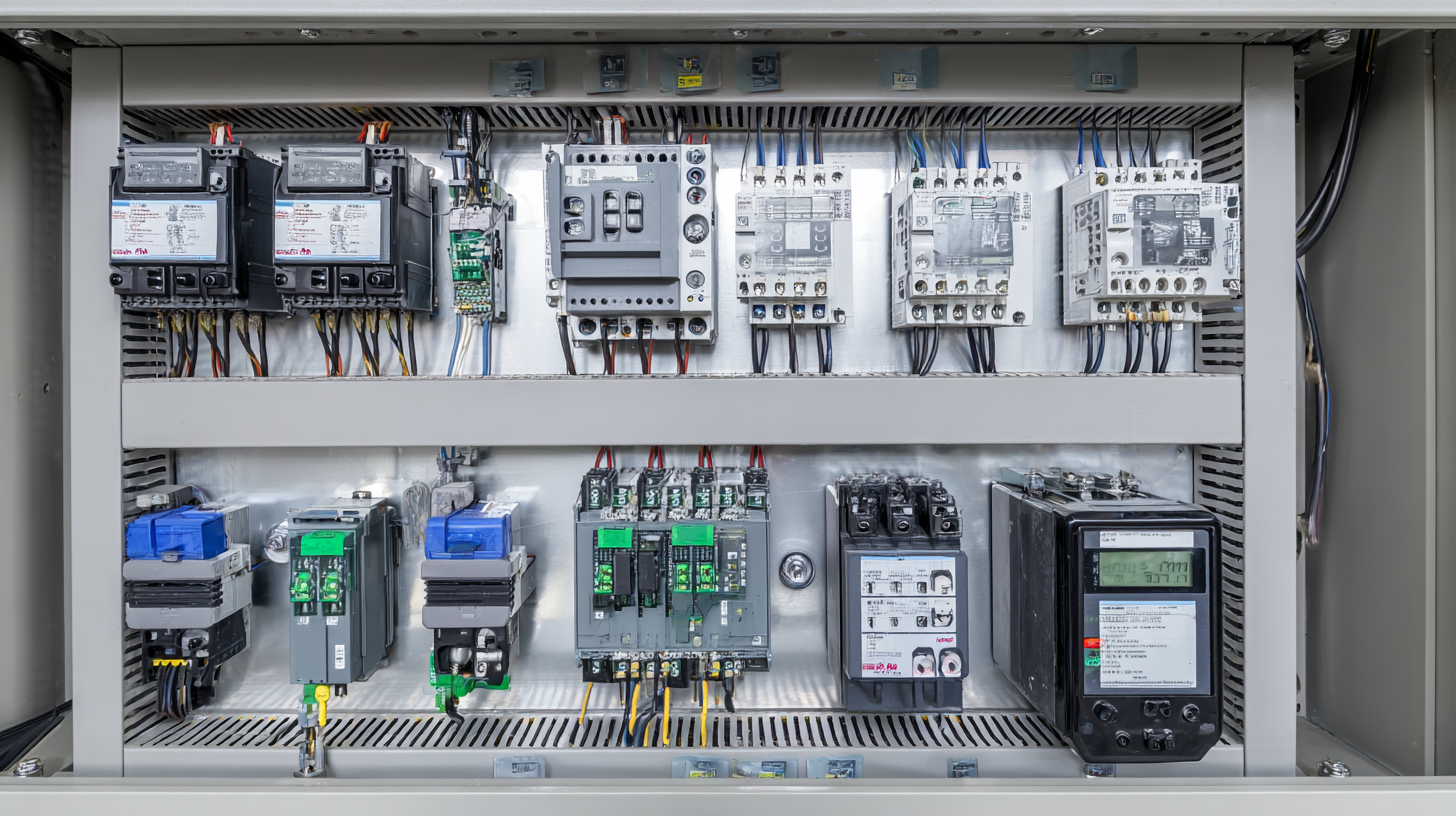

Understanding the Basics of Single Phase AC Drives and Their Applications

Single-phase AC drives are essential components in various industrial applications, particularly in situations where three-phase power is not readily available. These drives convert electrical energy into mechanical energy, allowing for precise control of motors. According to a report by MarketsandMarkets, the global market for AC drives is projected to reach $26.68 billion by 2026, reflecting a significant demand for efficient motor control solutions. This growth is driven by the increasing need for energy efficiency and automation in various sectors, including manufacturing, HVAC systems, and water distribution.

Understanding the basics of single-phase AC drives is crucial for optimizing their performance. These drives typically utilize pulse width modulation (PWM) technology to control the voltage and frequency supplied to the motor, enabling smooth acceleration and deceleration. A study by the International Energy Agency (IEA) highlights that integrating AC drives can improve overall energy efficiency by up to 50%, depending on the application. This efficiency not only reduces operational costs but also minimizes environmental impact, making single-phase AC drives a vital part of sustainable industrial practices. Companies adopting these technologies stand to benefit from enhanced performance, improved product quality, and reduced energy expenditures.

7 Best Ways to Enhance Efficiency with Single Phase AC Drive

| Method | Description | Benefits |

|---|---|---|

| 1. Proper Sizing | Select the right size drive for the application load requirements. | Improves energy efficiency and reduces operational costs. |

| 2. Regular Maintenance | Perform routine checks and maintenance on the drive. | Prevents breakdowns and extends the lifespan of the drive. |

| 3. Voltage Optimization | Adjust voltage settings to match operational needs. | Enhances performance while minimizing energy waste. |

| 4. Install Soft Starters | Use soft starters to reduce inrush current. | Protects equipment and improves reliability. |

| 5. Utilize Feedback Control | Implement feedback systems to adjust drive performance. | Increases accuracy and responsiveness of the system. |

| 6. Energy Recovery Systems | Incorporate systems that capture and reuse excess energy. | Reduces operational costs and carbon footprint. |

| 7. Advanced Control Algorithms | Adopt sophisticated algorithms for dynamic load management. | Maximizes efficiency and system reliability. |

Key Features of Single Phase AC Drives That Boost Efficiency

Single phase AC drives are essential for various applications, providing controlled speed and torque efficiencies. One of the key features that enhances efficiency is the capability to adjust the voltage and frequency precisely. This control allows users to tailor the output to the specific needs of their equipment, which not only improves performance but also helps in energy savings.

Tip: Regularly monitor and maintain the drive settings to ensure that the voltage and frequency are optimally configured for the load requirement. This practice can lead to significant reductions in energy consumption and operational costs.

Another important feature is the built-in protection mechanisms that prevent overload and overheating. These drives often come with thermal protection and overcurrent detection, which safeguard the equipment and prolong its lifespan. This not only enhances efficiency but also reduces downtime.

Tip: Invest in drives with advanced monitoring features. These can provide real-time data on performance metrics, allowing for proactive adjustments to maintain efficient operations. By leveraging these insights, users can maximize the benefits of their single phase AC drives while minimizing unexpected failures.

Top Techniques to Optimize Performance of Single Phase AC Drives

The optimization of single-phase AC drives is essential for enhancing performance and efficiency in various industrial applications. One of the top techniques to achieve this is through proper sizing of the AC drive units. A report by the International Electrotechnical Commission indicates that accurately sized drives can boost operational efficiency by up to 15%, reducing energy consumption significantly. This ensures that the motor runs at optimal performance levels, minimizing energy waste and operating costs.

In addition, implementing advanced control algorithms can lead to remarkable improvements in drive performance. Research shows that using vector control techniques can enhance torque response and reduce harmonic distortion, resulting in a potential efficiency improvement of 20% compared to traditional methods. Furthermore, regular maintenance and monitoring using Industry 4.0 technologies allow for real-time diagnostics and predictive maintenance, which can extend the lifespan of single-phase AC drives by 25%, according to a survey conducted by the Electrical Apparatus Service Association. By adopting these practices, industries can not only elevate performance but also foster sustainable operation methods.

Maintenance Tips to Ensure Long-term Efficiency in AC Drive Systems

Maintaining long-term efficiency in single-phase AC drive systems is crucial for optimal performance and cost-effectiveness. Regular maintenance not only extends the lifespan of the equipment but also significantly reduces downtime and operational costs. According to a report by the Electric Power Research Institute (EPRI), well-maintained AC drives can yield energy savings of 15-30% compared to poorly maintained units. This substantial saving highlights the importance of implementing a robust maintenance schedule.

Key maintenance practices include routine inspections of electrical connections and components to prevent overheating and failures, which are reported to account for nearly 30% of AC drive breakdowns. Additionally, ensuring that the firmware and software of the drive are updated can improve operational efficiency. The International Electrotechnical Commission (IEC) emphasizes the need for regular cleaning of dust and debris from the drives, as this simple procedure can improve cooling and prolong the system's life. Simply put, a strategic focus on maintenance not only enhances efficiency but also safeguards your investment in AC drive systems.

Case Studies: Successful Implementation of Single Phase AC Drives in Various Industries

The implementation of single-phase AC drives has revolutionized various industries, showcasing their adaptability and efficiency. One notable case study comes from the textile industry, where a manufacturer faced significant energy costs while running multiple sewing machines. By integrating single-phase AC drives, they not only streamlined their operations but also reduced energy consumption by 30%. This transition allowed for smoother operation and minimized wear on machines, leading to increased production capacity and a reduction in maintenance costs.

The implementation of single-phase AC drives has revolutionized various industries, showcasing their adaptability and efficiency. One notable case study comes from the textile industry, where a manufacturer faced significant energy costs while running multiple sewing machines. By integrating single-phase AC drives, they not only streamlined their operations but also reduced energy consumption by 30%. This transition allowed for smoother operation and minimized wear on machines, leading to increased production capacity and a reduction in maintenance costs.

In another instance, a food processing company adopted single-phase AC drives for its conveyor systems. The variable speed control enabled by these drives allowed the company to optimize the flow of materials, significantly improving the overall production rate. With this enhancement, they reported a decrease in bottlenecks during peak production hours, resulting in faster turnaround times and a boost in customer satisfaction. These examples illustrate the profound impact that single-phase AC drives can have across different sectors, proving that investing in such technology can lead to tangible benefits in both efficiency and profitability.

Related Posts

-

7 Reasons Why the Best 220v VFD Single Phase is a Game Changer for Your Business

-

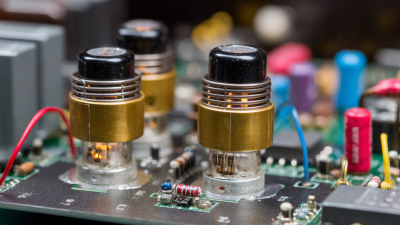

What Are EMI Filters and How Do They Enhance Device Performance?

-

7 Unique Benefits of Using Electromagnetic Brakes for Motor Applications

-

10 Best VFD Controllers You Need to Know for Optimal Performance

-

5 Essential Reasons to Choose EMI Filters for Your Electronic Devices

-

Discover High-Quality 220V VFD Single Phase Solutions from Leading Chinese Manufacturers