Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

How to Choose the Right 220V VFD Single Phase for Your Motor Applications

When selecting the ideal drive for your motor applications, understanding the intricacies of a 220V VFD single phase is crucial. Variable Frequency Drives (VFDs) empower users to control motor speed and torque with precision, enhancing efficiency and performance in various industrial tasks. With a plethora of options available, making the right choice can be daunting. This blog aims to simplify the decision-making process by providing insights into the essential features, specifications, and factors that should guide your selection of a 220V VFD single phase. Whether you are looking for improved energy savings, better motor control, or compatibility with specific motor types, we will cover best practices that ensure you invest wisely in a VFD that meets your operational needs. Embrace the journey towards optimized motor performance by learning how to choose the right 220V VFD single phase for your applications.

Understanding the Basics of 220V VFD Single Phase Technology

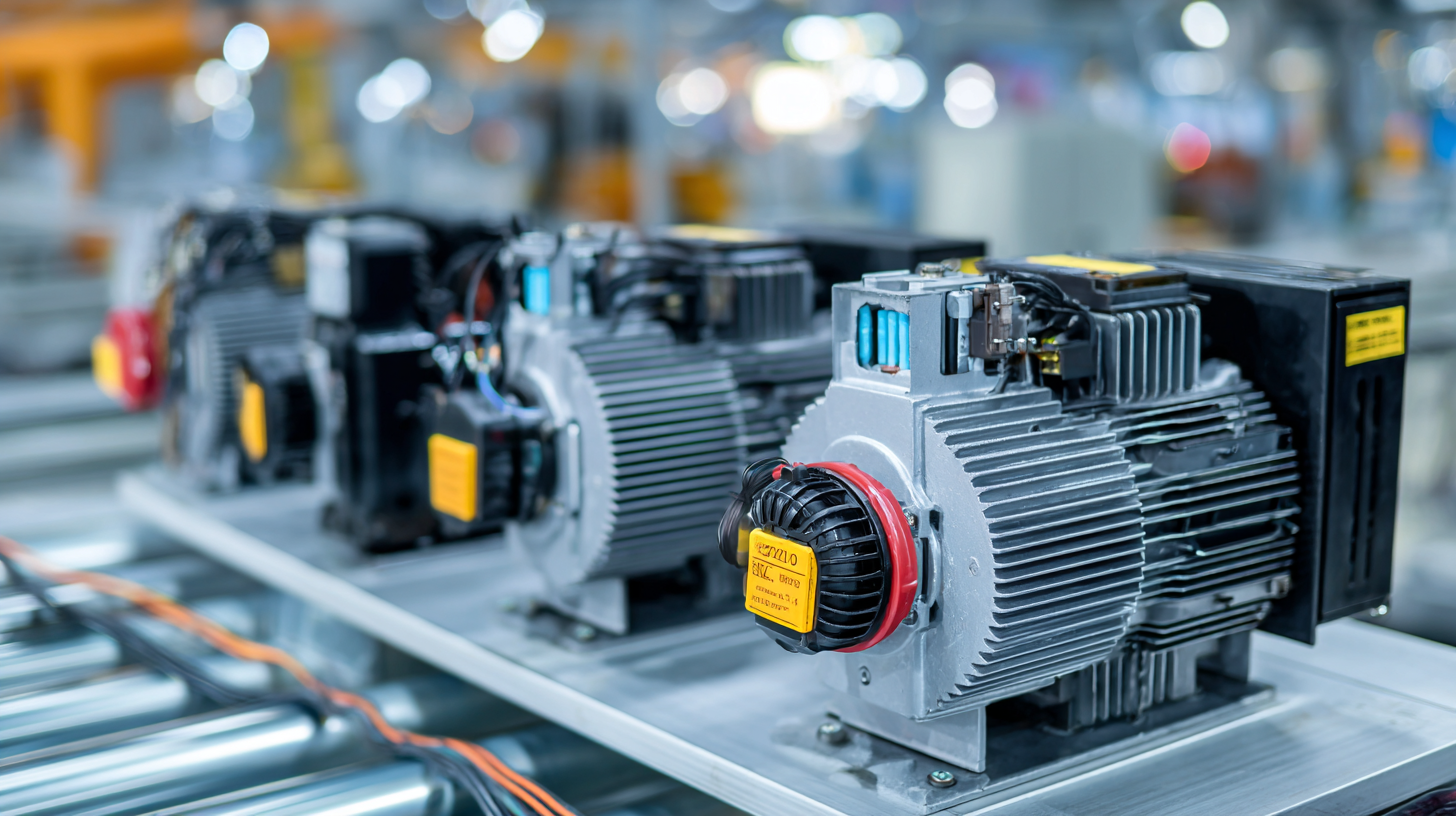

When diving into the world of 220V VFD single-phase technology, it’s essential to grasp the fundamental concepts that govern how these devices operate. Variable Frequency Drives (VFDs) are crucial in controlling the speed and torque of electric motors, which are increasingly vital in various industrial applications. With the growing integration of AI in industrial processes, the demand for efficient power solutions has expanded, as indicated by the latest reports highlighting that multi-phase power systems are becoming essential for high-load chips like CPUs and GPUs. This shift underscores the need for a nuanced understanding of how VFD technology can be optimized for specific applications.

The complexities of VFD systems extend beyond simple voltage ratings; they involve intricate relationships between frequency, motor design, and load characteristics. As industries pivot towards electrification, especially in sectors such as electric vehicles where efficient charging systems are paramount, understanding the specifications of 220V VFDs becomes even more critical. Recent data suggests that the demand for advanced VFD systems will continue to rise, influenced by the ongoing expansion of AI applications which require enhanced control over power management. This evolution in technology not only improves operational efficiency but also aligns with the broader trend toward sustainable energy solutions.

Key Considerations for Selecting VFDs for Various Motor Types

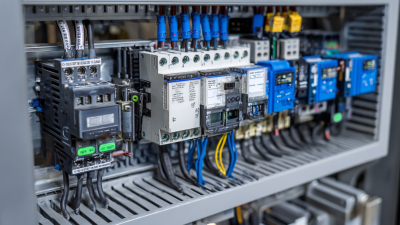

When selecting a Variable Frequency Drive (VFD) for single-phase 220V motor applications, it is essential to consider the specific requirements of different motor types. For example, standard induction motors benefit from a VFD that offers a continuous output voltage and current rating that matches the motor's specifications. According to a report by the International Electrotechnical Commission (IEC), mismatched VFD ratings can lead to overheating or reduced efficiency, thus impairing the overall system performance.

In contrast, for synchronous motors, it is critical to choose VFDs capable of providing precise control over speed and torque. A study by the Electric Power Research Institute (EPRI) highlights that selecting the right VFD can enhance energy efficiency by up to 30% in synchronous applications. Additionally, modern VFDs should feature advanced programming capabilities, allowing for customization to meet various load conditions. Integrating these considerations can ensure optimal performance and longevity for the motor systems, ultimately contributing to reduced operational costs.

In contrast, for synchronous motors, it is critical to choose VFDs capable of providing precise control over speed and torque. A study by the Electric Power Research Institute (EPRI) highlights that selecting the right VFD can enhance energy efficiency by up to 30% in synchronous applications. Additionally, modern VFDs should feature advanced programming capabilities, allowing for customization to meet various load conditions. Integrating these considerations can ensure optimal performance and longevity for the motor systems, ultimately contributing to reduced operational costs.

Compatibility Factors Between Motors and VFDs

When it comes to choosing the right 220V VFD (Variable Frequency Drive) for single-phase motor applications, compatibility between the motor and the VFD is crucial. Motors and VFDs operate on the principle of varying electrical frequency and voltage to control speed and torque. To ensure optimal performance, one must consider the motor's voltage ratings, frequency range, and power requirements. For instance, a motor designed for a specific voltage rating must align with the output voltage capabilities of the VFD. Mismatched voltages can lead to inefficient operation or even damage.

Additionally, it's essential to evaluate the operating characteristics of both the motor and the VFD. The torque requirements of the motor need to be met by the VFD's current output capacity. A VFD that does not adequately match the motor’s specifications may struggle to provide the necessary torque at low speeds, resulting in poor performance or motor failure. Furthermore, understanding the control method utilized by the VFD—be it V/f control or vector control—can greatly influence the motor's responsiveness and efficiency in different applications, ensuring that your motor runs smoothly and effectively.

Comparative Efficiency of VFD for Different Motor Types

Common Applications of 220V VFD Single Phase Systems

When selecting a 220V VFD single phase system for your motor applications, it's crucial to understand the specific needs of your projects. These VFDs are increasingly utilized in various sectors due to their efficiency in power management and motor control. Common applications include water and wastewater treatment, HVAC systems, and conveyor systems. According to a report from Transparency Market Research, the global variable frequency drive market is projected to reach $26.69 billion by 2027, with significant growth driven by such applications.

Tips for choosing the right VFD include assessing the motor's horsepower requirements and the nature of the load. For instance, water treatment facilities often require VFDs that can handle variable torque loads, enhancing their performance and reducing energy costs. Moreover, consider the environment where the VFD will be installed. For industrial settings with dust or moisture, selecting a VFD with appropriate enclosures, such as NEMA-rated housings, can improve reliability and longevity.

In addition to understanding application needs, familiarity with the control features offered by different VFDs can lead to better automation and efficiency. Certain advanced models provide options for real-time monitoring and diagnostics, which can be beneficial for predictive maintenance. Investing in a VFD that offers these capabilities can enhance operational efficiency and reduce downtime, ultimately delivering long-term savings.

Troubleshooting Tips for Optimal VFD Performance in Motor Use

When working with Variable Frequency Drives (VFDs) for your motor applications, troubleshooting is essential for ensuring optimal performance. One common issue is overheating of the VFD. This can often be traced back to insufficient cooling, so check that your drive has adequate airflow and is mounted in a location free from dust and debris. Additionally, ensure that the VFD is rated for the specific voltage and current requirements of your motor to prevent stress on the system.

Another frequent problem is incorrect programming of the VFD. It is critical to set the parameters according to your motor's specifications, including the proper frequency range and acceleration/deceleration settings. If the motor is experiencing erratic behavior, review the parameters again and consult the VFD manual or manufacturer for guidance on the specific settings for your application. Regularly updating the VFD firmware can also resolve any compatibility issues and improve overall performance, making it vital to stay informed about the latest updates and best practices.

Related Posts

-

7 Best Ways to Enhance Efficiency with Single Phase AC Drive

-

Unlocking Efficiency in Industrial Applications How to Use the Best Single Phase to 3 Phase Converter VFD

-

10 Best VFD Controllers You Need to Know for Optimal Performance

-

Exploring Motor Frequency Converter Alternatives for Enhanced Energy Efficiency and Performance

-

5 Essential Reasons to Choose EMI Filters for Your Electronic Devices

-

Exploring Innovative Alternatives to Frequency Drive Controllers for Enhanced Performance