Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

A Comprehensive Comparison of 220V VFD Single Phase Drives for Optimal Motor Performance

In today's industrial landscape, the demand for efficient and reliable motor control solutions has led to the increasing popularity of 220V VFD single phase drives. These Variable Frequency Drives (VFDs) not only enhance motor performance but also offer improved energy efficiency, making them a vital tool for many applications.

This expert guide aims to provide a comprehensive comparison of various 220V VFD single phase options available in the market, highlighting key features, advantages, and potential drawbacks. By understanding the differences between models and their specific functionalities, users can make informed decisions to optimize their motor systems for maximum performance.

Whether you're a seasoned engineer or a newcomer to motor control technology, this comparison will equip you with the necessary insights to select the most suitable drive for your needs.

Understanding the Basics of 220V VFD Single Phase Drives and Their Applications

When exploring the realm of 220V VFD (Variable Frequency Drive) single phase drives, it's essential to grasp their fundamental purpose and applications. VFDs are pivotal for controlling motor speed and torque efficiently, enabling precise operations in various industrial and commercial settings. From HVAC systems to conveyor belts, these drives can significantly enhance performance, energy savings, and longevity of motors.

**Tip:** When selecting a 220V VFD, consider the specific requirements of your application, including the motor's horsepower and the operational environment. This ensures compatibility and optimal performance.

Understanding how these drives interact with motors also helps in diagnosing issues and implementing effective solutions. With features like motor overload protection and built-in diagnostics, modern VFDs offer a range of functionalities that streamline operations and improve reliability.

**Tip:** Regular maintenance and periodic checks of VFD settings can prevent common issues, prolong the life of your equipment, and boost efficiency. Setting the right parameters based on the motor's characteristics is crucial for achieving the desired performance and avoiding damage.

A Comprehensive Comparison of 220V VFD Single Phase Drives for Optimal Motor Performance

| Model | Output Power (kW) | Input Voltage (V) | Rated Current (A) | Control Type | Frequency Range (Hz) | Efficiency (%) | Application |

|---|---|---|---|---|---|---|---|

| VFD-1 | 1.5 | 220 | 8 | V/F Control | 0-50 | 95 | Pumps, Fans |

| VFD-2 | 2.2 | 220 | 10 | Vector Control | 0-60 | 96 | Conveyor Systems |

| VFD-3 | 4.0 | 220 | 18 | Open Loop | 0-50 | 94 | Mixers, Compressors |

| VFD-4 | 3.0 | 220 | 14 | PWM Control | 0-60 | 97 | Cranes, Hoists |

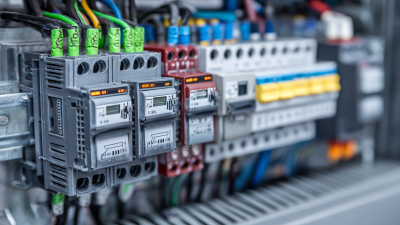

Key Features and Specifications to Look for in VFD Single Phase Drives

When selecting a variable frequency drive (VFD) for your single-phase applications, it’s essential to consider several key features that enhance motor performance and operational efficiency. One of the primary specifications to look for is the drive's power rating, which typically ranges from 50 W to 7 kW for various applications. Additionally, the capability of the drive to handle high dynamic loads can be crucial, particularly in situations requiring rapid acceleration and deceleration, making it vital for industries focused on precision and responsiveness.

Another critical factor is the modular design of the VFD, which allows for flexible integration and scaling as per operational demands. A well-designed VFD should decouple power and control units, facilitating easier maintenance and upgrades. Furthermore, ensuring the drive includes advanced features such as fault detection, energy efficiency algorithms, and compatibility with various motor types will greatly enhance system reliability. By focusing on these specifications, users can optimize their motor performance and minimize operational challenges, ensuring a smooth and efficient workflow in their applications.

Performance Metrics: Efficiency Ratings and Torque Control in VFD Drives

When evaluating 220V Variable Frequency Drives (VFDs) for single-phase applications, performance metrics such as efficiency ratings and torque control are crucial. According to a recent report by the International Energy Agency (IEA), VFDs can improve motor efficiency by 20-50% when compared to traditional methods of motor control. This efficiency boost is largely attributed to the VFD's ability to adjust the motor speed to match the load, reducing energy waste during operation. Metrics from manufacturers indicate that drives with higher efficiency ratings can lead to significant energy cost savings over time, translating to a quicker return on investment.

Torque control is another essential aspect of VFD performance. Precise torque management is vital for applications requiring consistent performance, such as conveyor systems or HVAC units. Research published in the Journal of Electrical Engineering indicates that advanced VFDs now feature better torque control algorithms, allowing for smoother acceleration and deceleration, which significantly reduces mechanical stress on equipment. With torque variations minimized, motors are less likely to overheat and wear out prematurely, enhancing the overall reliability and lifespan of the system. Such advancements underscore the importance of selecting the right VFD to optimize motor performance and ensure operational efficiency.

Comparative Analysis: Top Brands and Models of 220V VFD Drives in 2023

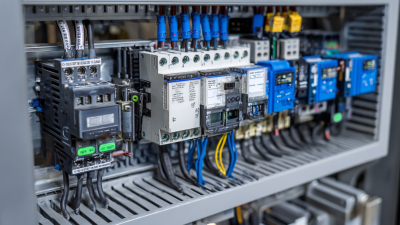

In the realm of motor control, 220V VFD (Variable Frequency Drive) single-phase drives have emerged as essential tools for enhancing efficiency and performance across various applications. The comparative analysis of top brands and models in 2023 reveals significant advancements in technology and usability. Key players like Siemens, Schneider Electric, and Mitsubishi have optimized their drives to cater to a range of motor specifications, ensuring seamless integration and superior control.

When evaluating these drives, factors such as energy efficiency, user-friendliness, and aftermarket support become crucial. For instance, Siemens' V20 series stands out for its compact design and robust performance, ideal for both simple and complex applications. Conversely, Schneider Electric's Altivar series excels in connectivity and monitoring features, making it a preferred choice for those seeking smart automation solutions. By understanding these distinctions, users can make informed decisions to achieve optimal motor performance tailored to their specific needs.

Tips for Installation and Maintenance to Maximize VFD Drive Lifespan and Efficiency

When it comes to maximizing the lifespan and efficiency of 220V VFD single-phase drives, proper installation and stringent maintenance protocols are paramount. According to industry reports, improper installation can lead to a reduction in drive lifespan by up to 50%. Ensuring correct input voltage levels, appropriate wiring, and the right environment can prevent issues such as overheating and electrical noise, which are detrimental to VFD performance. Utilizing a sound dampening strategy and ensuring adequate cooling can enhance operational reliability.

Maintenance is equally critical; regular checks for dust accumulation and electrical connections should be scheduled at least biannually. The National Electrical Manufacturers Association (NEMA) recommends routine testing of drive components to catch potential failures early, thereby reducing downtime. Additionally, adopting a predictive maintenance approach using real-time monitoring systems can provide valuable data analytics, which may lead to a 20-30% improvement in energy efficiency. This proactive strategy not only extends the operational life of the VFDs but also aids in maintaining optimal motor performance during their lifespan.

Related Posts

-

Discover How China is Revolutionizing Global Markets with Best 220v VFD Single Phase Solutions

-

Discover High-Quality 220V VFD Single Phase Solutions from Leading Chinese Manufacturers

-

Exploring Innovative Alternatives to Frequency Drive Controllers for Enhanced Performance

-

7 Reasons Why the Best 220v VFD Single Phase is a Game Changer for Your Business

-

Challenges When Choosing the Best Emi Filter for Vfd Applications

-

7 Unique Benefits of Using Electromagnetic Brakes for Motor Applications