Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

What Are EMI Filters and How Do They Enhance Device Performance?

In today's technologically advanced landscape, the importance of EMI filters in enhancing device performance cannot be overstated.

Electromagnetic interference (EMI) presents a significant challenge for electronic devices, with studies indicating that up to 30% of device failures can be attributed to such interference. As wireless communication and digital systems proliferate, the demand for effective EMI filters has surged, leading to a projected market growth rate of 10% annually through 2025, according to a recent report by MarketsandMarkets.

EMI filters not only protect sensitive components but also ensure compliance with stringent regulatory standards. By mitigating noise and improving signal integrity, these filters play a crucial role in optimizing device functionality and reliability, making them indispensable in a wide range of applications, from consumer electronics to industrial machinery.

In today's technologically advanced landscape, the importance of EMI filters in enhancing device performance cannot be overstated.

Electromagnetic interference (EMI) presents a significant challenge for electronic devices, with studies indicating that up to 30% of device failures can be attributed to such interference. As wireless communication and digital systems proliferate, the demand for effective EMI filters has surged, leading to a projected market growth rate of 10% annually through 2025, according to a recent report by MarketsandMarkets.

EMI filters not only protect sensitive components but also ensure compliance with stringent regulatory standards. By mitigating noise and improving signal integrity, these filters play a crucial role in optimizing device functionality and reliability, making them indispensable in a wide range of applications, from consumer electronics to industrial machinery.

Understanding EMI Filters: Definition and Importance in Electronics

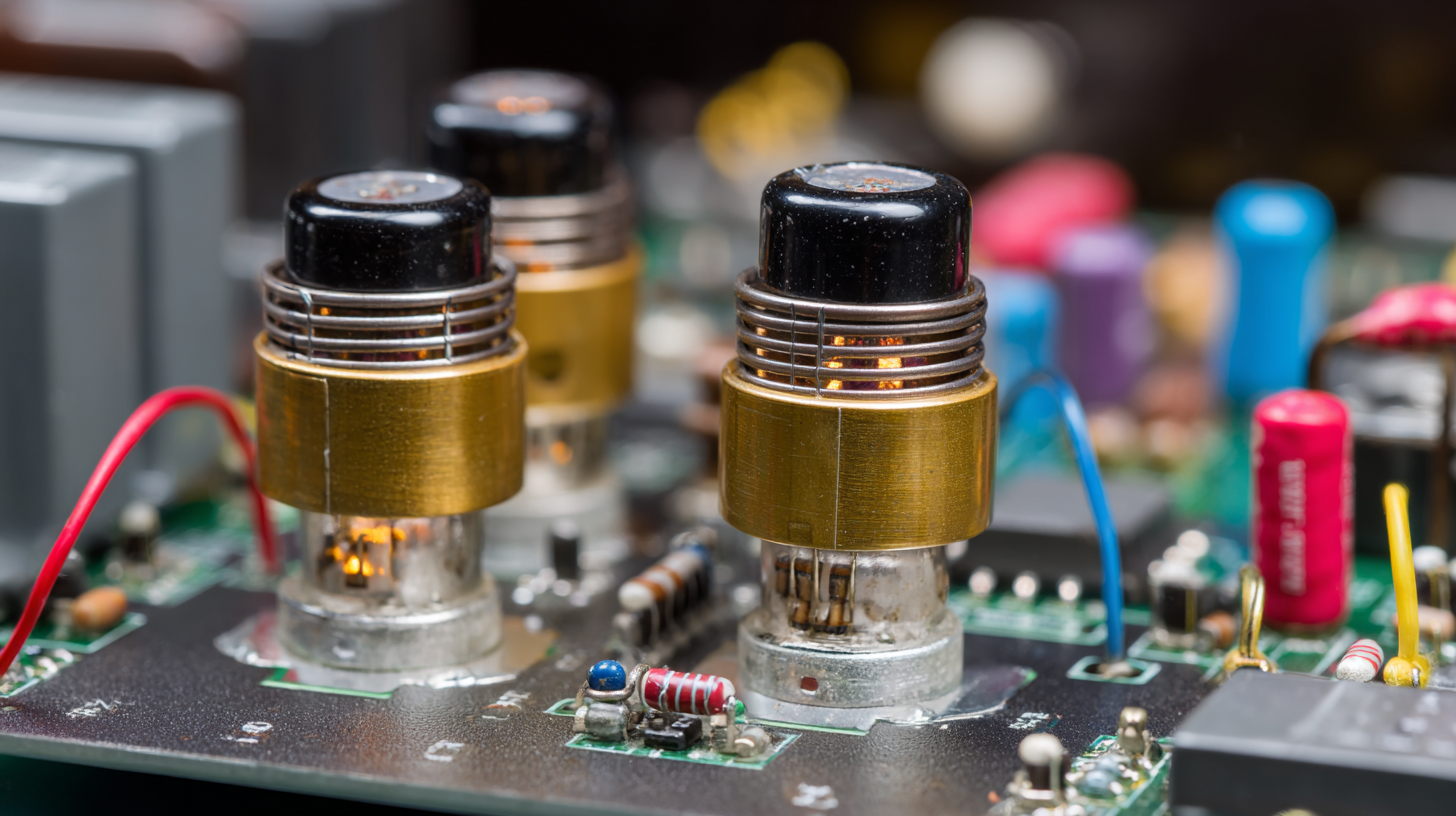

Electromagnetic interference (EMI) filters are crucial components in electronics, designed to suppress unwanted electromagnetic noise that can disrupt device performance. These filters operate by allowing desired signals to pass while attenuating noise frequencies, thereby ensuring compliance with increasingly stringent electromagnetic compatibility (EMC) regulations across various industries. As industries expand their reliance on power electronic-based converters, the importance of EMI filtering becomes paramount to safeguard signal integrity and enhance device reliability.

When designing EMI filters for switched-mode power converters, it’s essential to consider the specific frequency ranges of potential interference. Implementing filters that target these specific ranges can dramatically improve the efficiency of power conversion and minimize energy losses.

**Tips:**

1. Always assess the environment in which your device will operate; this helps in selecting the appropriate filter design.

2. Regularly update your EMI filtering techniques to stay compliant with evolving regulations, especially in sectors like aerospace and defense.

3. Consider using innovative materials and shielding solutions that provide improved protection against both EMI and RF interference, ensuring mission success in critical applications.

What Are EMI Filters and How Do They Enhance Device Performance?

| Filter Type | Application | Frequency Range (kHz) | Typical Insertion Loss (dB) | Benefits |

|---|---|---|---|---|

| Passive EMI Filters | Consumer Electronics | 10 - 1000 | 20 - 40 | Cost-effective, Reliable |

| Active EMI Filters | Industrial Applications | 1 - 30 | 40 - 60 | Higher performance, Adaptive |

| Common Mode Chokes | Telecommunications | 100 - 10000 | 30 - 50 | Effective noise suppression |

| Differential Mode Filters | Signal Processing | 5 - 500 | 15 - 25 | Improved signal integrity |

| LC Filters | Power Supply Units | 50 - 1000 | 20 - 30 | High efficiency, Low distortion |

Key Types of EMI Filters and Their Specific Applications in Device Performance

Electromagnetic Interference (EMI) filters play a crucial role in enhancing device performance by reducing noise and ensuring compliance with regulatory standards. There are several key types of EMI filters, each tailored for specific applications. Common types include capacitive filters, inductive filters, and combined LC filters. Capacitive filters are favored in applications like power supplies and telecommunications, where high-frequency noise suppression is essential. According to a report by MarketsandMarkets, the global EMI filtering market size is expected to grow from USD 3.7 billion in 2020 to USD 5.2 billion by 2025, highlighting the increasing importance of these filters in modern electronic devices.

Inductive filters, on the other hand, excel in power electronics and automotive applications, providing better attenuation of lower frequency noise. They utilize inductors to block high-frequency components while allowing lower frequencies to pass through. A study published by Grand View Research indicates that the automotive segment will witness significant growth, driven by the integration of advanced driver-assistance systems (ADAS) which necessitate robust EMI protection. Likewise, combined LC filters are gaining traction across various sectors including medical and industrial applications, thanks to their ability to effectively mitigate both common and differential mode noise simultaneously. This variety of EMI filters ensures that devices operate smoothly, leading to enhanced performance and longevity.

Impact of EMI Filters on Signal Integrity and Overall Device Efficiency

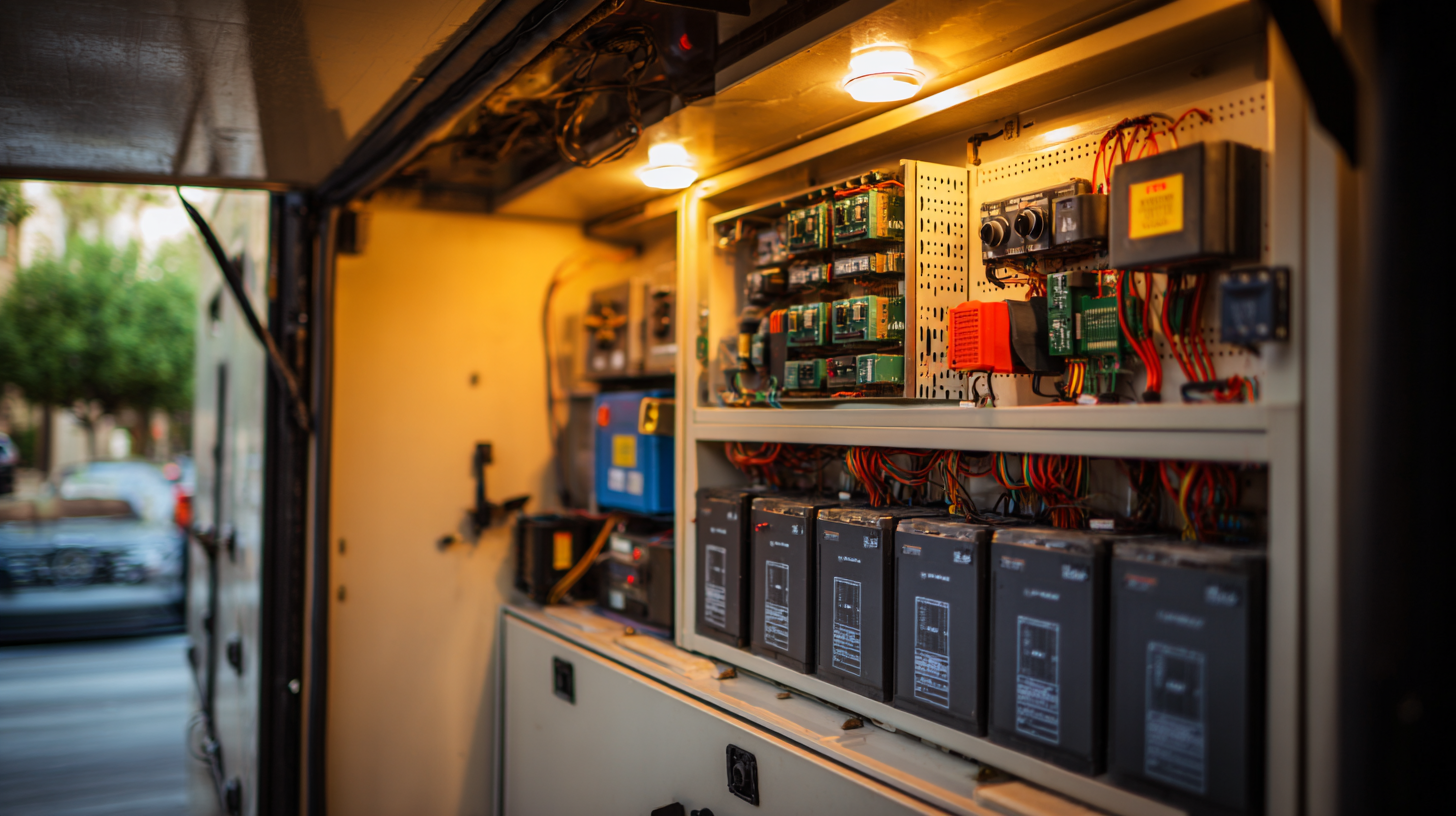

Electromagnetic interference (EMI) filters play a crucial role in enhancing signal integrity within electronic devices. By suppressing unwanted electromagnetic noise, these filters ensure that the signals passing through the circuitry are clear and stable. This clarity is essential for maintaining the accuracy and reliability of data transmission in various applications, from consumer electronics to industrial machinery. A device burdened with EMI can suffer from data corruption, leading to malfunctions or performance degradation. Thus, implementing effective EMI filtering is fundamental to preserving the quality of the signal.

Moreover, the overall efficiency of a device is significantly influenced by EMI filters. By mitigating interference, these filters reduce the energy wasted in signal distortion and improve the performance of power management systems. Enhanced efficiency not only leads to better functionality but can also extend the lifespan of electronic components by minimizing stress induced by fluctuating signals. As a result, devices equipped with high-quality EMI filters can operate at optimal levels, ensuring both peak performance and longevity while meeting stringent regulatory standards for electromagnetic compatibility.

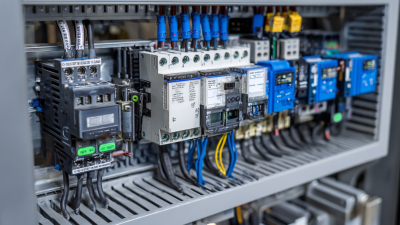

Industry Standards and Testing Methods for Evaluating EMI Filter Effectiveness

Electromagnetic Interference (EMI) filters play a critical role in ensuring the optimal performance of electronic devices by reducing unwanted noise and interference. To evaluate the effectiveness of these filters, industry standards such as IEC 61000-4-6 and MIL-STD-461 provide guidelines for testing various electromagnetic disturbances. These standards help manufacturers ensure compliance and enhance the reliability of their products in diverse operating environments. Recent studies indicate that devices tested against these standards demonstrate a performance improvement of up to 30% in environments with high EMI.

To maximize the benefits of EMI filters, it’s essential to select the right type for your specific application. For instance, passive filters are typically more effective for reducing high-frequency noise, while active filters can adapt to varying interference levels. Additionally, thorough testing should be conducted under real-world conditions to ensure that the filters perform effectively across all potential interference sources.

Tips: Regularly assess the EMI performance of your devices against established standards to ensure ongoing compliance. Additionally, consider implementing a testing phase during product development to identify potential EMI challenges early on, ultimately leading to a more robust design and enhanced performance.

EMI Filter Effectiveness across Different Frequency Bands

This chart illustrates the effectiveness of EMI filters at various frequency bands, showcasing how performance improves with the use of different filter types.

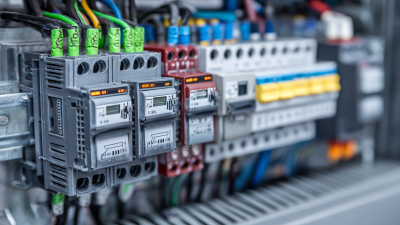

Future Trends in EMI Filter Technology and Their Potential Impact on Electronics

As the electronics industry continues to evolve, the demand for advanced Electromagnetic Interference (EMI) filter technologies is on the rise. According to a recent report by Research and Markets, the global EMI filter market is projected to reach $3.2 billion by 2027, driven by the increasing need for efficient electromagnetic compatibility in electronic devices. This growth is largely attributed to emerging applications in industries such as automotive, telecommunications, and consumer electronics, where robust EMI filtering solutions can significantly enhance device performance and reliability.

Future trends in EMI filter technology are leaning towards miniaturization and integration with other circuit components. The development of compact, multi-functional filters can potentially reduce space and cost while improving performance. Moreover, advancements in materials such as ferrite and ceramic are expected to enhance the effectiveness of these filters in high-frequency environments, with some estimates suggesting a 30% improvement in filtering efficiency. This will enable better operation of sensitive electronic devices in crowded frequency environments, paving the way for more reliable products.

Tip: When designing devices, consider the placement and selection of EMI filters early in the design phase to achieve optimal performance and compliance with regulatory standards. Furthermore, staying informed about the latest advancements in filter technology could provide a competitive edge in developing next-generation electronics.

Related Posts

-

5 Essential Reasons to Choose EMI Filters for Your Electronic Devices

-

5 Reasons Why Frequency Drive Controllers Are Essential for Global Procurement Success

-

Exploring Innovative Alternatives to Frequency Drive Controllers for Enhanced Performance

-

A Comprehensive Comparison of 220V VFD Single Phase Drives for Optimal Motor Performance

-

Challenges When Choosing the Best Emi Filter for Vfd Applications

-

7 Reasons Why the Best 220v VFD Single Phase is a Game Changer for Your Business