Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

5 Reasons Why Frequency Drive Controllers Are Essential for Global Procurement Success

In today's rapidly evolving industrial landscape, the integration of advanced technologies such as frequency drive controllers has become essential for organizations aiming to achieve global procurement success. According to a report by MarketsandMarkets, the global variable frequency drive market is projected to reach $24.54 billion by 2026, driven by the increasing need for energy efficiency and process optimization.

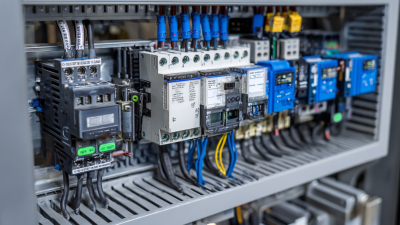

Frequency drive controllers play a pivotal role in enhancing operational efficiency by enabling precise control over motor speed and torque, significantly reducing energy consumption and operational costs. As businesses strive to streamline procurement processes and enhance competitiveness, the ability to leverage cutting-edge automation technologies like frequency drive controllers is no longer a luxury but a necessity.

This blog will explore the five key reasons why adopting frequency drive controllers is crucial for overcoming procurement challenges and achieving sustainable growth in a global marketplace.

The Critical Role of Frequency Drive Controllers in Efficient Procurement

In today's fast-paced global market, frequency drive controllers play a pivotal role in streamlining procurement processes. These devices regulate motor speed and torque, enhancing the efficiency of various industrial operations. By optimizing energy consumption, companies can reduce operational costs and improve sustainability, making frequency drive controllers an integral part of the procurement strategy.

One of the key benefits of frequency drive controllers is their ability to enhance equipment longevity. By preventing motors from operating at full speed unnecessarily, these controllers reduce wear and tear, which translates to lower maintenance costs and fewer disruptions in supply chains. When considering procurement, it is essential to evaluate the impact of drive technologies on your overall asset management.

Tip: When selecting frequency drive controllers for your organization, prioritize models that offer monitoring and diagnostic features. This capability allows for real-time performance assessment and can help identify potential issues before they escalate, ensuring smoother operations. Additionally, consider integrating these controllers into your existing systems for streamlined procurement processes that promote efficiency and responsiveness.

Enhancing Supply Chain Performance with Frequency Drive Technologies

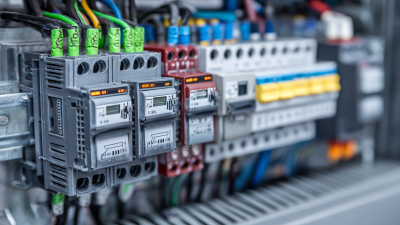

Frequency drive technologies play a pivotal role in enhancing supply chain performance, particularly in industries where efficiency and energy consumption are critical. According to a report by the International Energy Agency (IEA), industrial motors account for nearly 70% of global energy consumption in the manufacturing sector. By implementing frequency drive controllers, businesses can optimize motor speeds, significantly reducing energy use by 20-50%. This reduction not only leads to lower operational costs but also supports sustainability goals, making it a win-win for both the supply chain and the environment.

Moreover, frequency drive technologies contribute to improved equipment reliability and reduced maintenance costs. A study conducted by the Electric Power Research Institute (EPRI) found that operations using variable frequency drives (VFDs) experienced a 30% decrease in equipment maintenance needs. This reliability enhances supply chain resilience, allowing companies to better respond to market fluctuations and disruptions. With the increasing complexity of global supply chains, the strategic integration of frequency drive controllers not only boosts performance but also equips businesses with the agility necessary to thrive in today's competitive landscape.

Moreover, frequency drive technologies contribute to improved equipment reliability and reduced maintenance costs. A study conducted by the Electric Power Research Institute (EPRI) found that operations using variable frequency drives (VFDs) experienced a 30% decrease in equipment maintenance needs. This reliability enhances supply chain resilience, allowing companies to better respond to market fluctuations and disruptions. With the increasing complexity of global supply chains, the strategic integration of frequency drive controllers not only boosts performance but also equips businesses with the agility necessary to thrive in today's competitive landscape.

Cost Reduction Strategies Through Frequency Drive Integration

The integration of frequency drive controllers (FDCs) in procurement strategies is reshaping the landscape of cost reduction in various industries. As organizations increasingly pivot towards digital solutions, the incorporation of FDCs allows for enhanced control over energy consumption, translating to significant cost savings. These devices optimize the operation of electric motors, leading to reduced energy use and minimized operational costs. As businesses seek sustainability, energy efficiency becomes paramount, especially in the context of smart grids and renewable energy, where FDCs can facilitate smoother energy management and integration.

Moreover, embracing advanced technologies like Artificial Intelligence (AI) and the Internet of Things (IoT) further amplifies the benefits of FDCs in supply chain management. By leveraging these technologies, companies can refine their procurement processes, enhance inventory management, and improve supplier relationships. The growing emphasis on digitalization not only drives down costs but also strengthens the overall efficiency of operations. As the market for variable frequency drives continues to expand—with projections indicating a significant increase in value—organizations that adopt these technologies will undoubtedly gain a competitive edge in global procurement initiatives.

Cost Reduction Strategies Through Frequency Drive Integration

Improving Supplier Relationships with Advanced Frequency Control Systems

The introduction of advanced frequency control systems in global procurement processes has become a game changer for enhancing supplier relationships. By integrating frequency drive controllers, organizations can achieve precise control over machinery and production processes, leading to optimized performance and higher quality outputs. This efficiency not only meets the demands of suppliers but also fosters a collaborative environment where expectations can be clearly set and met.

Additionally, frequency drive controllers enable real-time monitoring and feedback, allowing suppliers to adjust their strategies based on accurate data. This data-driven approach encourages transparency and accountability, vital components in building trust with suppliers. When suppliers recognize that a company invests in advanced technology for smoother operations, they are more likely to engage positively, resulting in stronger partnerships and mutual benefits. By leveraging these systems, businesses can streamline their supply chains and enhance overall operational agility, leading to a more sustainable procurement strategy.

Future-Proofing Global Operations Using Frequency Drive Innovations

In the rapidly evolving landscape of global procurement, future-proofing operations has become essential. Frequency drive innovations play a pivotal role in achieving this goal. According to a report by MarketsandMarkets, the variable frequency drives (VFD) market is projected to reach $19.26 billion by 2026, growing at a CAGR of 5.4%. This growth underscores the increasing importance of frequency drive controllers in optimizing energy consumption and enhancing operational efficiency across various sectors.

Implementing frequency drive technology not only contributes to significant energy savings but also enables businesses to adapt to changing market demands swiftly. A study by the U.S. Department of Energy revealed that VFDs can reduce energy use in electric motors by 20-50%, which is crucial in an era where sustainability is a key procurement criterion. By leveraging these advanced controllers, organizations can ensure compliance with global energy regulations while minimizing operational costs, thus securing a competitive edge in an interconnected marketplace. As industries strive to enhance their resilience, the integration of frequency drive systems is integral to creating adaptable and efficient global operations.

Related Posts

-

Exploring Motor Frequency Converter Alternatives for Enhanced Energy Efficiency and Performance

-

Exploring Innovative Alternatives to Frequency Drive Controllers for Enhanced Performance

-

5 Essential Reasons to Choose EMI Filters for Your Electronic Devices

-

7 Unique Benefits of Using Electromagnetic Brakes for Motor Applications

-

Discover High-Quality 220V VFD Single Phase Solutions from Leading Chinese Manufacturers

-

Challenges When Choosing the Best Emi Filter for Vfd Applications