Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

Essential Tips for Choosing a Servo Drive Controller?

Choosing the right servo drive controller can significantly impact the efficiency of automation systems. According to a report by MarketsandMarkets, the servo drive market is expected to reach $12.4 billion by 2026, reflecting its critical role in various industries. These systems facilitate precise control over motor functions, essential in robotics and manufacturing.

Expert John Smith, a leading authority in automation technology, states, "Selecting an effective servo drive controller is pivotal for optimal machine performance." However, many companies underestimate the importance of compatibility between the controller and the motor. This oversight can lead to inefficiencies and potential malfunctions, which are costly to resolve.

Understanding the specifications and applications of various servo drive controllers is essential. Some controllers may excel in specific environments but fail in others. Not every company defines its needs clearly, leading to regrettable choices. Thus, careful consideration based on industry research and expert recommendation is critical in avoiding common pitfalls.

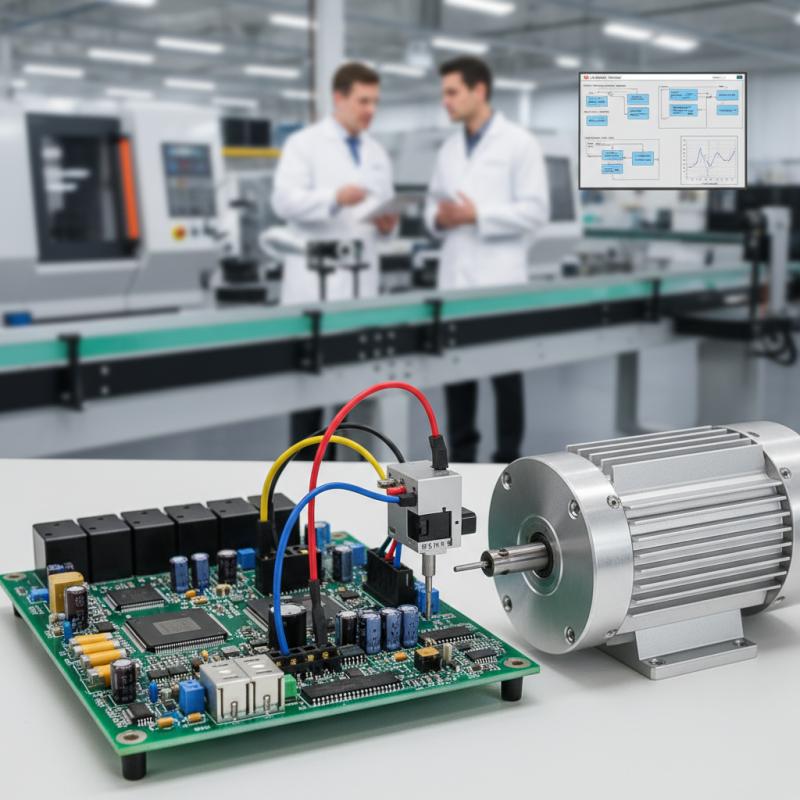

Understanding the Basics of Servo Drive Controllers

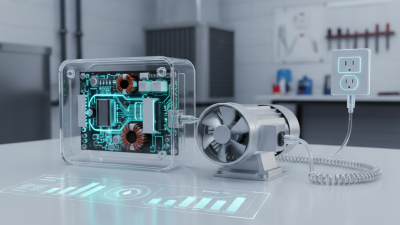

When delving into servo drive controllers, it's essential to grasp their core functions. A servo drive regulates the power to a motor, ensuring precise control. These controllers interpret commands and adjust motor speed, position, and torque effectively. Understanding this fundamental aspect aids in selecting the right system.

Selecting a servo drive can feel overwhelming. Consider compatibility with your motor. Check voltage and current specifications. Look for features like feedback types, which help ensure accuracy. However, not all applications require the latest technology. Sometimes, opting for simpler solutions might be more efficient.

It’s also vital to factor in your specific application requirements. Think about the environment where the servo drive will be used. Will it face vibrations or temperature fluctuations? It is easy to overlook details in a rush to choose. Take time to reflect on your needs. Prioritizing small details can lead to better overall performance and longevity in operation.

Key Factors to Consider When Selecting Servo Drive Controllers

When selecting a servo drive controller, several key factors must be weighed carefully. The type of application can greatly influence the choice. For example, high-speed applications may require specific features. Look for controllers that offer quick response times. They should support various feedback devices. Compatibility is crucial here.

Another important aspect is the control method. Some systems rely on position control. Others need speed or torque control. Make sure the controller matches your needs. It’s also wise to consider ease of integration. Check if the controller has the necessary communication protocols.

The environment where the controller operates is worth thinking about too. Is it in a clean room or a harsh setting? Dust and temperature variation can affect performance. Lastly, consider future scalability. You might need more features down the line. Choosing wisely now can save headaches later.

Types of Servo Drive Controllers and Their Applications

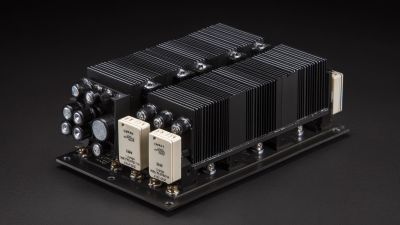

When selecting a servo drive controller, understanding its types and applications is crucial. There are several types of servo drive controllers, including AC servo drives, DC servo drives, and digital servo drives. Each type has unique features that cater to different industrial needs. For instance, AC servo drives are widely used in robotics and CNC machines due to their high efficiency and smooth operation. According to recent industry reports, the global servo drive market is projected to grow at a CAGR of 7.5%, indicating increased demand for these controllers.

Digital servo drives are another popular choice. They offer precise motion control, making them ideal for applications requiring high accuracy. In automated manufacturing, these controllers often integrate with PLC systems. However, they can be complex to set up and may require specialized knowledge. As industries adopt more automation, simplicity in design may be overlooked. This reliance can cause issues if the personnel are not adequately trained.

On the other hand, DC servo drives have a distinct advantage in terms of startup torque and speed control. They're prevalent in conveyor systems and small machines. However, they are less efficient over time and might face overheating issues if not monitored. As you weigh your options, consider not just the specifications, but also the long-term implications of your choice. Each type presents its own challenges and benefits, demanding careful analysis.

Essential Tips for Choosing a Servo Drive Controller

| Type of Servo Drive Controller | Key Features | Common Applications | Control Mode | Advantages |

|---|---|---|---|---|

| AC Servo Drive | High efficiency, precise control, low noise | Robotics, CNC machinery, automation | Speed and Torque Control | Reliable performance, excellent dynamic response |

| DC Servo Drive | Simple to control, cost-effective | Print finishing, packaging machinery | Position Control | Easy integration and maintenance |

| Brushless Servo Drive | High performance, long lifespan | Industrial robots, medical equipment | Position, Speed, and Torque Control | Low maintenance costs, high reliability |

| Integrated Servo Drive | Compact design, cost-effective solutions | Conveyors, assembly lines | Speed Control | Less wiring, space-saving design |

Evaluating Performance Specifications of Servo Drive Controllers

When selecting a servo drive controller, performance specifications should be a primary consideration. Look at the controller's responsiveness. This means how quickly it reacts to input commands. A fast response time enables precise control in dynamic applications. Also, explore the torque and speed ratings. Higher ratings can lead to better performance in heavy-duty tasks.

Consider how these specifications match your application needs. For instance, a high torque controller may not be necessary for light assembly tasks. However, machines that involve heavy lifting require robust specifications.

Tips for choosing include assessing your load requirements. Calculate the weight and speed needed for your tasks. Ensure the controller can handle peak loads without overheating. Don't ignore the feedback mechanisms. They are crucial for achieving accuracy in motion. Evaluate if you need closed-loop or open-loop systems. Each has its own benefits and drawbacks worth exploring. Balancing these factors can be challenging but vital for optimal performance.

Common Mistakes to Avoid in Choosing Servo Drive Controllers

Choosing a servo drive controller requires careful consideration. One common mistake is overlooking the compatibility. Ensure the controller matches your motor specifications. Impedance mismatches can lead to performance issues. Check voltage and current ratings; they must align precisely.

Another mistake is neglecting the communication protocols. Not all controllers support the same protocols. This oversight can result in integration challenges. Sometimes, the specifications look good on paper but fail in real-world applications. Verify that the controller works seamlessly with your existing system.

Cost is often a critical factor, but cheap options can be tempting. These may lack essential features or reliability. This could lead to more expenses in the long run. Testing the controller’s performance is vital. Ignoring this aspect can result in unanticipated downtimes. Always err on the side of caution and evaluate before making a decision.

Related Posts

-

Understanding the Importance of EMI Filters for VFD Applications in Modern Industry

-

Exploring the Impact of ATO Single Phase VFD on Energy Efficiency and Cost Savings in Modern Applications

-

7 Best Ways to Enhance Efficiency with Single Phase AC Drive

-

How to Choose the Right 220V VFD Single Phase for Your Motor Applications

-

What Are EMI Filters and How Do They Enhance Device Performance?

-

Understanding Single Phase VFD: Benefits, Applications, and Buying Guide